Monitor Vapour pressure deficit: use VPD sensor data for smarter growing

Measuring vapor pressure deficit has become increasingly important in horticulture. In this article we talk about vapor pressure deficit, commonly referred to as VPD. Why is this metric relevant and what value provides a VPD sensor? Let’s dive in!

What is VPD?

The VPD essentially tells how much moisture the air can hold during a certain temperature. The metric is used to measure how close the air is to saturation. The VPD is the difference between the amount of moisture in the air and how much moisture the air can potentially hold when it’s saturated.

Still with us? VPD can be a little bit difficult to comprehend if you’re unfamiliar with the term. It is usually measured in kilopascal (kPa).

Magazine Maximum Yield illustrates: “A VPD of zero means the air is 100 percent saturated with water vapor. A low VPD of around 0.3 kPa means the air is still holding a lot of water vapor, while a high VPD means very dry air with minimal water vapor, but a considerable amount of drying capacity.”

Why is VPD important in horticulture?

If the VPD is zero, plants can not transpire effectively. So the VPD is an important factor in creating an optimal growing environment. It can influence various key elements, which are connected to each other. As VPD increases:

- The uptake of CO2 decreases

- The increasing difference in vapor pressures between the leaf and the air causes the crop to evaporate

- VPD increase → transpiration increase → thirst! The plant needs to draw more water from its roots

- All this combined, leads to more stress. And that could lead to a weaker plant.

So VPD affects the plants loss of water (transpiration). Sometimes the air in a greenhouse gets too dry during the day. This can cause a plant to ‘turn off’. When the air is too dry, photosynthesis will stop to prevent the plant from exhausting. Photosynthesis is the process used by plants to convert sunlight, water and CO2 into oxygen and energy that is used for the growth. The crop will miss hours of daylight which leads to a decline in health. An optimum VPD can help in the prevention of mold and plant diseases.

Research in tomato production in 2017 showed that VPD regulation efficiently moderated plant water stress and maintained the plants water balance. The researchers concluded that when you regulate the VPD, you’ll be more efficient with irrigation.

30MHz Sensor Catalogue

30MHz Sensor Catalogue

Designed for accuracy, flawless connectivity and remote placement, these tools are built to withstand the elements in all growing contexts. Build your digital infrastructure with a combination of sensors that suit your needs, and add new data sources at any time.

What is the best VPD for my crop?

As with most metrics in horticulture, ideal VPD differs by crop and conditions. Optimum VPD levels depend on the growing phase. Researchers Heidi Wollaeger and Erik Runkle wrote an article about the use of VPD in greenhouse ornamentals and vegetables. They suggest: “Growers should aim to have fairly low VPD – for example 0.3 kPa – when rooting cuttings in greenhouses. This will reduce the drying of young plants, thereby reducing the frequency of misting and watering required to keep plants hydrated. However we recommend maintaining a VPD greater than 0.5 kPa in greenhouses while finishing plants. Especially when there’s a dense plant canopy. Plants will be able to transpire, cool themselves and be less stressed while the environment is less conducive to disease.”

Pointed Microclimate Sensor: Measuring VPD in a greenhouse.

Measuring Relative humidity or VPD?

Growers use Relative Humidity to understand the environment of a greenhouse or polytunnel and monitor growing conditions. In general, VPD is a better metric to use when you experience issues caused by humidity. According to research by the Michigan State University in the USA, VPD is more useful to measure than relative humidity. The researchers point out that VPD is independent of temperature. “When measuring plant transpiration and water loss, it provides greater insights than temperature and relative humidity on their own.”

In general, VPD is a better metric to use when you experience issues caused by humidity. “Vapor pressure deficit is a more accurate humidity measurement that takes into account the effect of temperatures on the water-holding capacity of the air, which is what ultimately drives transpiration of the leaf surface”, writes Maxium Yield.

In short: The effect humidity has on plants also depends on temperature. So just checking the relative humidity can’t always give you the most valuable insights. For a complete image you have to take VPD into account.

How to influence the VPD?

It can be a challenge to find the right VPD level for crops. The right VPD depends on the stage of the growing process. If you’re controlling an indoor growing environment, you’re having the advantage of pushing the buttons. You can steer towards the optimum VPD. There are a few ways you can influence the VPD:

Increase the VPD ↑

- Increase the temperature = increases the VPD

- Increase the light intensity = increases the VPD

- Decrease humidity = increases the VPD

Decrease the VPD ↓

- Decrease the temperature = decreases the VPD

- Decrease the light intensity = decreases the VPD

- Increase humidity = decreases the VPD

How to use a VPD sensor?

The math behind VPD is complicated. Don’t worry. You don’t have to spend hours calculating and juggling with numbers. We calculate the VPD for you. Together with growers 30MHz developed the Pointed Microclimate Sensor. This is a multifunctional sensor combination which measures various metrics like VPD, dewpoint and relative humidity.

A lot of our customers use this sensor as their VPD sensor. Their experience is that this sensor calculates the VPD more efficiently than their climate computer.

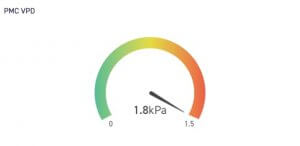

This sensor uses leaf temperature and humidity measurements to continuously capture microclimate at close range. The VPD is calculated inside this sensor. In the 30MHz platform you can create a widget to see the current VPD. Our wireless sensor can send real time data and alerts to any device. So you can get a notification message or email if the VPD level in your environment gets too low or too hight (like you see in the image below).

Want to analyse the VPD in detail? Create a line graph. This enables you to see what the VPD was at a specific time. You can create a line for a different metric as well. So you can see the influence of humidity on the VPD for example.

What do our customers think about using the VPD sensor?

Madestein UK specialty is growing lettuce and basil. Monitoring their crops with the Pointed Microclimate Sensor, Madestein found that driving VPD higher improved the harvest quality and consistency, leading to a reduction in wastage and better shelf life. Director Jonathan Zwinkels: “Having greater insight into what the plant is doing with 30MHz smart sensing tech is really useful, and helps us focus on improving quality and reducing disease risk. We see the impact of capturing metrics that we previously didn’t have.”

Horticultural consultant Chris Need used the platform during one of the hottest summers in recent years: “Screen settings and irrigation timings were manipulated to reduce leaf and air temperatures and reduce VPD peaks. 30MHz tech allowed us to go beyond a traditional approach of just looking at the environment— we could actually monitor the plants themselves and identify and minimise stress, something you wouldn’t spot using other tools.”

30MHz is typing… Our extended support team is ready to chat!

At 30MHz we think it’s important that our users can use our platform in an optimal way. At times you may have questions and you would like some help from our support team. Email and our support page filled with helpful articles were your go to’s. But we thought it was time for something extra… ...Read more

New 30MHz connect casing: How we protect your tech

To make sure your dataflow is fully protected, 30MHz introduces a new connect casing: waterproof, dust proof and even resistant to hits. This special shield will last longer and ensure a reliable dataflow from the connected sensor. What does that full protection mean? That’s what we will explain in this article. Watertight: resistant to wetness ...Read more

Most popular sensors for your greenhouse

As a grower, you know that optimal crop development starts with precise monitoring of your cultivation environment. But how do you transform raw data into actionable insights for your crops? This is where our wireless sensors and the 30MHz platform come together. Our sensors measure essential variables such as VPD, dew point, moisture deficit, EC, ...Read more