The (r)evolution of digital horticulture

Technology and the greenhouse. In 2020 it’s an inseparable whole, but of course, that has not always been the case. To understand how horticulture in the Netherlands has been able to conquer such an incredibly strong position in the world market, it is good to understand its history. And what role does digitisation play in its preservation and further growth?

The first industrial greenhouses appear around 1850, in which growers grow grapes. They are simple glass sockets, leaning against a wall on one side. It will then take another fifty years before those grape greenhouses are completely made of glass and are heated. Before that, flat glass (single-glass and Lentse windows) was used on flat forcing trays for the cultivation of vegetables and plants. The first so-called ‘department stores’ (interlinked greenhouses) were built around 1940 by raising single-glass builds. A salient detail is that the floristry sector has adapted greenhouses earlier than the fruit and vegetable growers.

Several factors play a decisive role in the emergence of the Netherlands’ largest and globally highest concentrated horticultural area, the Westland. In addition to location (close to the important port city of Rotterdam) and availability of labour, the presence of light (at that time the most important climatological factor), a moderate climate, a light sandy soil and sufficient freshwater are important.

The industry continues to evolve so it doesn’t depend solely on the whims of Mother Nature. Gardeners discover that they can achieve a higher yield by growing in heated greenhouses with as much glass as possible. Plants grow faster if they get more light and have a constant warm environment. This means that other products that otherwise only grow in warm countries can be grown.

Technological developments such as artificial heating, artificial light, water management and disease control follow each other in rapid succession. These developments are necessary because the growing economy leads to an increase in labour costs. Labour productivity must increase and production-increasing technologies are therefore inevitable. On the other hand, there is also increasing competition from the south of Europe. In response to this, more and more supply companies are emerging. Climate computers increasingly form the basis of a modern greenhouse. The start of measuring and storing climate data is a fact.

The first digital steps

The climate computer not only controls heating, irrigation and light but also offers a wealth of data. Analysis take place on the computer itself, which has found a place in the grower’s office. Specialized cultivation advisers and consultants make their appearance. This leads to an intensification of data analysis in combination with a very large plant physiological knowledge. The analysis options within the climate computer itself are becoming less and less satisfactory. As a result, the demand for this type of software is increasing. LetsGrow.com is one of the first parties to focus on this. Born from climate computer manufacturer Hoogendoorn, the company provides analyses and advice with the aim of improving production quality and accurate harvest forecasts. The algorithms are based on the data generated from the greenhouse and plant physiology.

More and more industry-specific programs are set up, such as the closed greenhouse, the semi-closed greenhouse, the stacked greenhouse, the floating greenhouse, the greenhouse as an energy source and the greenhouse of 2020. One of the most eye-catching initiatives is Next Generation Growing. In this, a solution is sought for various bottlenecks in greenhouse horticulture, such as energy consumption, use of space, the emission of carbon dioxide and other substances, etc. The program stands for an energy-efficient cultivation method with optimal production. This new approach focuses on the crop and avoids unnecessary use of fossil fuels. According to the initiators, energy savings of at least 30% can be achieved, whereby product quality and sales are often better thanks to an optimal greenhouse climate.

Horticulture sector meets 30MHz

One of the conditions for Next Generation Growing is data at crop-level. Sensors that measure the microclimate of the crops and not of the greenhouse in general as the climate computers have done until then. 30MHz is a party that creates that kind of hardware at that moment. Not yet based on the immediate needs of the horticultural sector, but aimed at companies from the port area and the facility management branch. At one of the first horticultural fairs that 30MHz attends, the enormous demand for these types of data sources is immediately apparent.

What the growers do not yet know is that there is a data platform behind the 30MHz hardware that can not only accommodate the data from sensors but can also be linked to the climate computer systems and sensors that are already being used. In the years after the introduction of the Amsterdam company in one of the most intriguing industries in the Netherlands, 30MHz gained a stable foothold. The platform accelerates the development of analysis tools that help growers more than ever to utilise the greenhouse on every square centimetre and meet today’s challenges. Growers, consultants and distributors, in collaboration with Artificial Intelligence, analyse the countless data points and communicate via the same platform about the next step to be taken in the production process.

Autonomous cultivation on a commercial scale

In an article on HortiDaily, Jitse Schöne and Gerjo Engbers from research company Delphy elaborate on this topic: “Through a connection with the climate computer, we can monitor what is happening on location. This allows us to provide advice via our Dashboard, draw up charts and transfer knowledge. That makes – together with the cultivation planning that we make – a complete overview. It is now even moving in the direction that we will soon be going autonomously on a large commercial scale, starting with the parameters misting, windows and screens.”

“It is coming to a point where we, in the Netherlands, can use digital systems to monitor what growers are doing anywhere in the world. The supervision will also mainly take place from the Netherlands. This gives you more control from one central place. That offers opportunities to watch and manage several companies at the same time. We are going from a green thumb in the greenhouse to green fingers on the computer. The green thumb will certainly remain necessary, but we are heading towards more data-driven support for companies,” says Jitse.

Images:

Schema, voorstellende de ontwikkeling van de kas uit muur, orangerie of zaadbed, uit: E.W.B. Muijzenberg, A history of greenhouses, Wageningen 1980, p. 144.

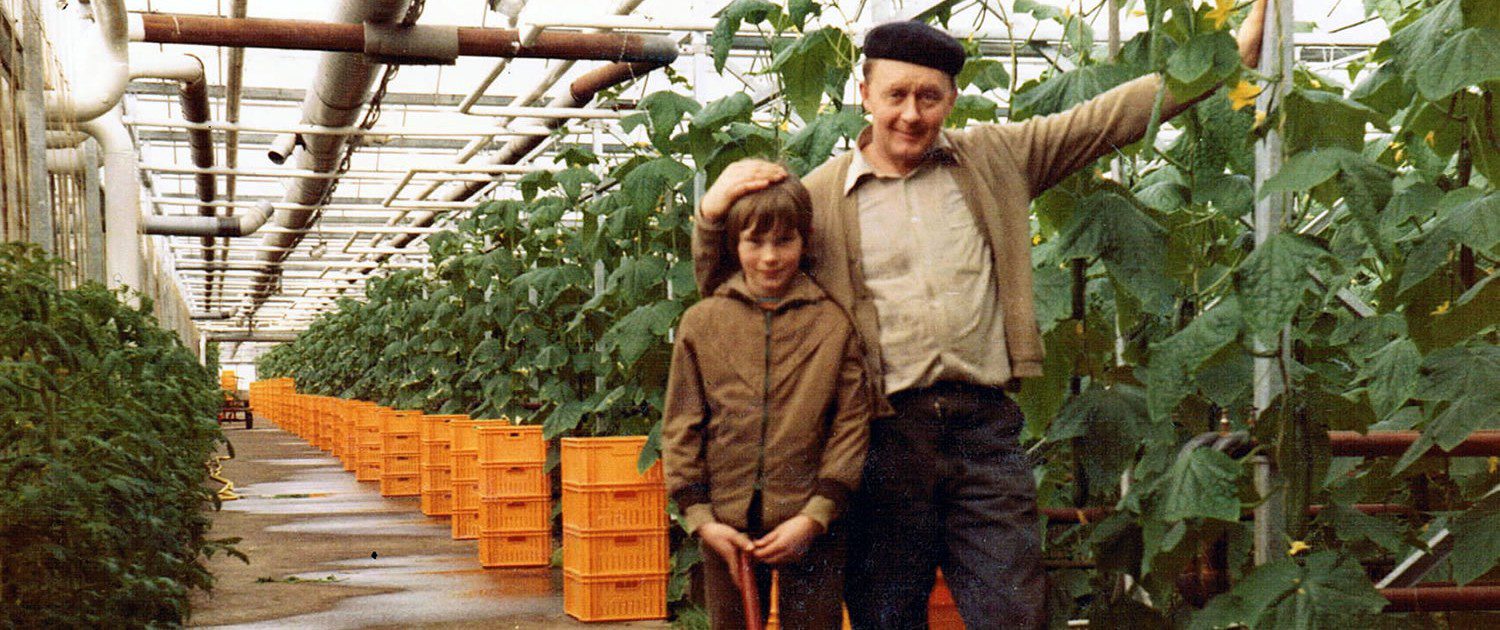

Sjors (Gergely) Kosdi met zoon, Kwekerij Noord-Oost BV

Sources:

https://kasseninnederland.nl/wp-content/uploads/Kassenboek-web-06-Hoofdstuk-6.pdf

https://spinlab.vu.nl/wp-content/uploads/2016/09/scriptiefinaal-AardeEconomie-AstridButijn.pdf

30MHz is typing… Our extended support team is ready to chat!

At 30MHz we think it’s important that our users can use our platform in an optimal way. At times you may have questions and you would like some help from our support team. Email and our support page filled with helpful articles were your go to’s. But we thought it was time for something extra… ...Read more

New 30MHz connect casing: How we protect your tech

To make sure your dataflow is fully protected, 30MHz introduces a new connect casing: waterproof, dust proof and even resistant to hits. This special shield will last longer and ensure a reliable dataflow from the connected sensor. What does that full protection mean? That’s what we will explain in this article. Watertight: resistant to wetness ...Read more

Most popular sensors for your greenhouse

As a grower, you know that optimal crop development starts with precise monitoring of your cultivation environment. But how do you transform raw data into actionable insights for your crops? This is where our wireless sensors and the 30MHz platform come together. Our sensors measure essential variables such as VPD, dew point, moisture deficit, EC, ...Read more